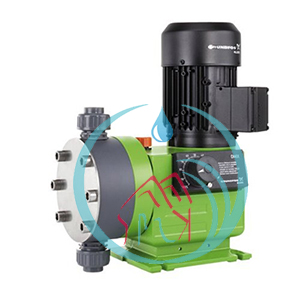

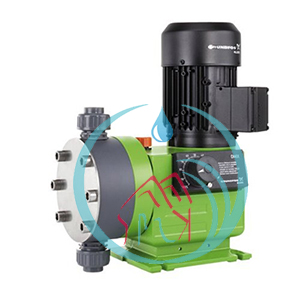

Grundfos DMX Dosing Pump range has proven its worth in dosing applications worldwide. With their robust diaphragm-based design and their high quality motor DMX pumps require minimum maintenance and are best choice for many dosing applications. Grundfos DMX range is highly versatile : it covers a wide flow range and offers a variety of dosing head sizes, materials and accessories.

Feature and Benefits of Grundfos DMX Dosing Pump :

- Accurate dosing – all the time

The diaphragm design make sure, that the dosing flow fluctuation is -/+ 1.5% (DMX 227: +/- 2%) and the linearity deviation is +/- 4% at all times. This allows very precise dosing of chemicals – as much as necessary, as little as possible - Smooth and low – pulsation dosing

The DMX range combines sophisticated drive technology and gear kinematics to ensure smooth and low-pulsation dosing without pressure peaks. - Compact design saves money and space

DMX pumps are available in 12 different dosing head sizes. The compact design allows placing several pumps right next to each other in confined spaces. The extra capacity offered by double-heat versions can also be used to gain higher flow rates for a single chemical. - Perfect material selection for housing and liquid-wetted parts

The smaller DMX models have plastic housing offering chemical resistance and all the protection necessary for many applications. The larger models have a robust cast-aluminium housing with epoxy coating to meet all application needs. - Motor and VFD to match application needs

For application with specific motor requirements, the versatile DMX range offers Ex-classified or ATEX-certified high-quality motors. The VFD (Variable Frequency Drive) has inputs and outputs for analog and digital signal, and an interface for fields bus communication (Profibus, Profinet). - Accessories ensure perfect operation of the entire system

A wide range of accessories specially designed for the DMX range helps optimize performance : AR control electronics, integrated relief valve, dosing controller, diaphragm leakage detection, servomotor for automatic stroke-length adjustment, PTC motors with Variable Frequency Drive (VFD), pressure-loading valves and pulsation dampers.

Applications :

Disinfection, coagulation, flocculation, precipitation, etc, in :

- Drinking water treatment

- Waste water treatment

- Pulp and paper industry

- Textile industry

- Cleaning water treatment

- Food and beverage industry, dairies

- Cooling tower water treatment

- Low-pressure boiler feed water treatment

- Agriculture

- Irrigation

- Fertigation

Technical Data :

- Capacity, Q : maximum 4000 l/h (pump with two heads: 2 x 4000 l/h)

- Pressure, p : maximum 10 bar

- Liquid temperature : maximum 50℃